Ever wonder how that incredible shoe design in your head makes the leap from a simple drawing to something you can actually wear?

Have you ever bought a pair of shoes online, anticipating their arrival with excitement, only to be utterly disappointed by the quality, fit, or even the way they look in person? Maybe the stitching is off, the materials feel cheap, or they're just plain uncomfortable. It's frustrating, right? Often, that disconnect boils down to a failure in translating the initial design into a real-world product, and that's where the unsung hero – the shoe factory – plays a vital role.

The factory is much more than just a place where shoes are assembled; it's a crucial partner in bringing a designer's vision to life, offering invaluable expertise in materials, construction techniques, and manufacturing processes. A collaborative relationship between the designer and the factory ensures that the final product aligns with the original concept while meeting the highest standards of quality, comfort, and durability.

This article will peel back the curtain on the fascinating relationship between shoe designers and the factories that transform their creative visions into tangible footwear, giving you a better understanding of the entire process.

Understanding the Crucial Role of Shoe Manufacturing in Design Implementation

Okay, let’s dive in! I'm going to break down how shoe factories contribute way more than you might think to the final product. It's not just about slapping some soles on leather (or vegan leather!); it's a collaborative dance.

Think of it this way: the designer is the architect, and the factory is the construction crew. The architect creates the blueprint, but the crew needs to know the best materials, the sturdiest construction methods, and how to troubleshoot any unexpected issues. The same applies to shoes!

Why isn’t my shoe design perfect from the start?

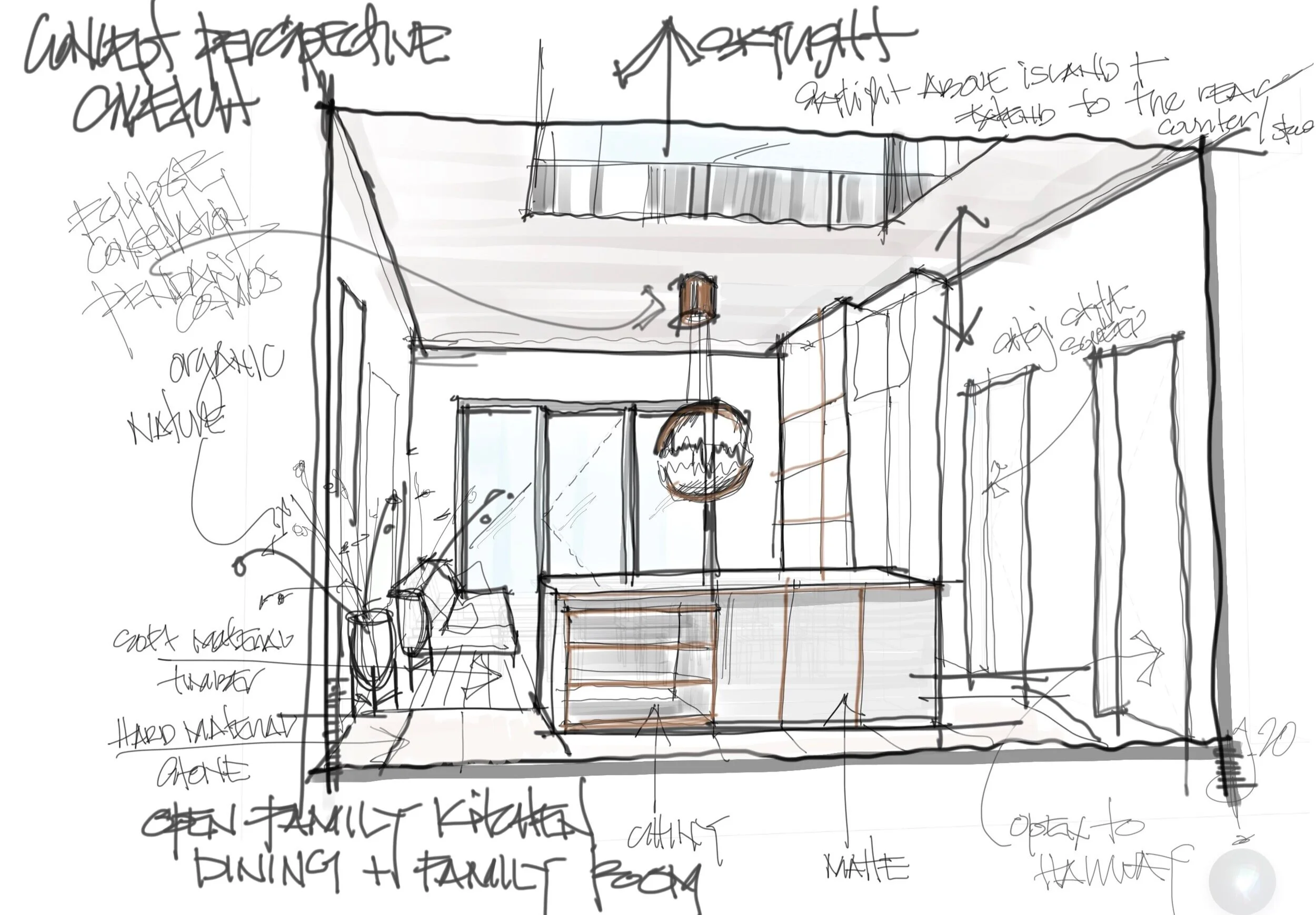

Several factors contribute to the challenges in translating a design into a tangible product. Firstly, designs are often conceived in a 2D space (sketches, digital renderings), whereas shoes are inherently 3D objects. This requires careful consideration of volume, fit, and how the materials will behave when molded and stitched together.

Secondly, the properties of different materials can vary significantly. A designer might envision a shoe made from a specific type of leather, but the factory might discover that this leather is difficult to work with at scale or doesn't meet the required durability standards. Sourcing materials that both match the aesthetic visionandfunction correctly is key.

Finally, the design needs to be manufacturable. A beautiful design with intricate details might be impractical or too costly to produce efficiently. The factory's expertise in manufacturing processes is essential for identifying potential bottlenecks and suggesting design modifications to optimize production.

How can I improve the shoe production process?

Good question! It's all about communication, expertise, and a willingness to adapt. Here's a breakdown: Collaboration is Key:Open communication between the designer and the factory is essential. Regular meetings, clear communication of design specifications, and prompt feedback are crucial for preventing misunderstandings and ensuring that the final product meets expectations. Sharing prototypes and samples early in the process allows both parties to identify potential issues and address them before they become major problems.

Leverage Factory Expertise: Don't be afraid to lean on the factory's experience. They know the ins and outs of material sourcing, construction techniques, and manufacturing processes. Ask for their input on material selection, design modifications, and potential challenges. They can often suggest alternative solutions that achieve the desired aesthetic while optimizing manufacturability and cost-effectiveness.

Embrace Prototyping: Creating physical prototypes is crucial for evaluating the fit, comfort, and overall aesthetics of a shoe design. The factory can produce prototypes using different materials and construction methods, allowing the designer to fine-tune the design and identify any potential issues before mass production. It's much easier (and cheaper!) to fix a problem in the prototype stage than after thousands of shoes have been manufactured.

Understand Material Limitations: Designers should educate themselves about the properties and limitations of different materials. This knowledge will help them make informed decisions about material selection and avoid designs that are impractical or difficult to manufacture. The factory can provide valuable guidance on material sourcing and suggest alternative materials that meet the desired aesthetic and functional requirements.

Focus on Quality Control: Implement rigorous quality control measures throughout the manufacturing process. This includes inspecting materials, monitoring production processes, and conducting final product inspections. Addressing quality issues early on can prevent costly rework and ensure that the final product meets the highest standards of quality.

What role does technology play in shoe creation?

Technology is revolutionizing the way shoes are designed and manufactured, impacting everything from initial sketches to final production.

3D Modeling and Printing: 3D modeling software allows designers to create detailed virtual prototypes of their shoe designs, visualizing every aspect of the shoe before it's even physically produced. 3D printing technology enables the creation of physical prototypes quickly and efficiently, allowing designers to experiment with different designs and materials.

CAD/CAM Software: Computer-aided design (CAD) and computer-aided manufacturing (CAM) software streamline the design and manufacturing processes. CAD software allows designers to create precise digital models of their designs, while CAM software translates these models into instructions that can be used to control automated manufacturing equipment.

Automation: Automated manufacturing processes, such as robotic stitching and automated cutting machines, can significantly improve efficiency and reduce labor costs. Automation also helps to ensure consistent quality and minimize errors.

Data Analytics: Data analytics can be used to monitor production processes, identify bottlenecks, and optimize efficiency. By analyzing data on material usage, production times, and defect rates, manufacturers can identify areas for improvement and implement strategies to enhance productivity and reduce costs.

Virtual Reality (VR) and Augmented Reality (AR): VR and AR technologies are increasingly being used in the design and prototyping stages. VR allows designers to immerse themselves in a virtual environment and experience their shoe designs from different perspectives. AR allows designers to overlay virtual designs onto real-world objects, enabling them to visualize how a shoe will look on a person's foot.

What makes a shoe factory a "good" partner?

Finding the right factory is as important as having a killer design. Here's what to look for: Experience and Expertise:A good factory will have a proven track record of producing high-quality shoes. They should have experience working with a variety of materials and construction techniques and be able to provide valuable guidance on design modifications and manufacturing processes. Ask for examples of their past work and talk to other designers who have worked with them.

Communication and Collaboration: Look for a factory that is responsive, communicative, and willing to collaborate closely with you throughout the design and manufacturing process. They should be able to provide clear and timely feedback on your designs and be open to suggestions and modifications. Regular meetings and open lines of communication are essential for ensuring that the final product meets your expectations.

Quality Control Standards: A good factory will have rigorous quality control standards in place to ensure that every shoe meets the highest standards of quality. They should inspect materials, monitor production processes, and conduct final product inspections to identify and address any potential issues.

Ethical and Sustainable Practices: In today's world, it's increasingly important to choose a factory that adheres to ethical and sustainable practices. Look for factories that prioritize worker safety, fair wages, and environmental responsibility. Ask about their labor practices, waste management policies, and use of sustainable materials.

Fair Pricing: While you don't want to sacrifice quality, it's also important to find a factory that offers fair pricing. Get quotes from multiple factories and compare their prices and services. Be sure to factor in factors such as material costs, labor costs, and shipping costs when evaluating different quotes.

So, what does ethical manufacturing really mean?

Ethical manufacturing is more than just a buzzword; it's about ensuring that workers are treated fairly, the environment is protected, and the production process is transparent and accountable.

Fair Labor Practices: Ethical factories prioritize the well-being of their workers. This includes providing safe working conditions, paying fair wages, and ensuring that workers have the right to organize and bargain collectively. There should be no child labor or forced labor.

Environmental Responsibility: Ethical factories minimize their environmental impact by reducing waste, conserving resources, and using sustainable materials. They may invest in renewable energy, implement water conservation measures, and recycle materials.

Transparency and Accountability: Ethical factories are transparent about their production processes and accountable for their actions. They are willing to share information about their labor practices, environmental policies, and sourcing practices.

Choosing an ethical factory demonstrates a commitment to social and environmental responsibility and can enhance a brand's reputation.

Hopefully, you now have a clearer understanding of how vital factories are in turning those initial sketches into the shoes you love (or sometimes, unfortunately, dislike!). The factory's expertise, combined with the designer's vision, is what ultimately determines the success of a shoe. So next time you're admiring a pair of shoes, remember the journey they took and the collaboration that made them possible.

The collaboration between designers and manufacturers shapes the evolution of footwear, influencing not just what we wear on our feet, but how we experience the world, one step at a time. Take a moment to appreciate the craftsmanship and collaborative spirit behind your favorite pair – and perhaps consider the journey of future designs, knowing that your choices can support both artistry and ethical production.